Smart Factory Industry 4.0

TPST Services Pvt Ltd is a one-stop service provider for a whole suite of solutions that supports Smart Manufacturing for customers to achieve Industry 4.0 goals.

Machine integration and the advent of the Internet of Things have ameliorated the entire manufacturing process and have made the industry progress towards the smart factory. Remote dashboards enable users to access on-site computer systems from distant locations. Automated Meter Reading has effectively aided in the hands-free collection of data from meters. Digital twins of physical objects and big data analytics have proven to be beneficial to the various processes involved. Augmented Reality and Mixed Reality experiences have showcased the various combinations and interactions between the real world and digital world.

Goals of Smart Factory:

- Software & Solutions

- Automation and Equipment Solutions

- Customization and Enhancement services

Software & System Solutions

- Equipment Connectivity for SECS/GEM & Non-SECS/GEM solutions

- IOT, Systems integration, data acquisition, mining and analytics to process data into useful management information and reports

- Wired or wireless data acquisition embedded IOT system with DIO/AI modules

- Security system such as CCTV system solutions

- Provide software solutions for hand-free automation

- Application software solutions such as RECC, EMS, OEE, RMS, TLMS, etc

Automation and Equipment Solutions:

- Provide conceptual, design, fabrication, software development & assembly for some customize automation machines

- Provide automation hardware & software

- Provide hand-free automation solutions such as AGV/AMR, Robot arm/Cobot, Smart rack, etc

Customization and Enhancement services:

- Users defined application (software & hardware)

- Provide tailor made automation and equipment based on customer requirements

- Networking & connectivity solutions

- Provide software & system solutions as per customer requirements

Field Of Expertise:

- Remote Equipment Control Center (RECC)

- Equipment monitoring System (EMS)

- Overall Equipment Effectiveness (OEE)

- Equipment Recipe Management System (RMS)

- Tool life Monitoring and Control System (TLMS)

- Temperature & Humidity Monitoring & Control System (T/HMCS)

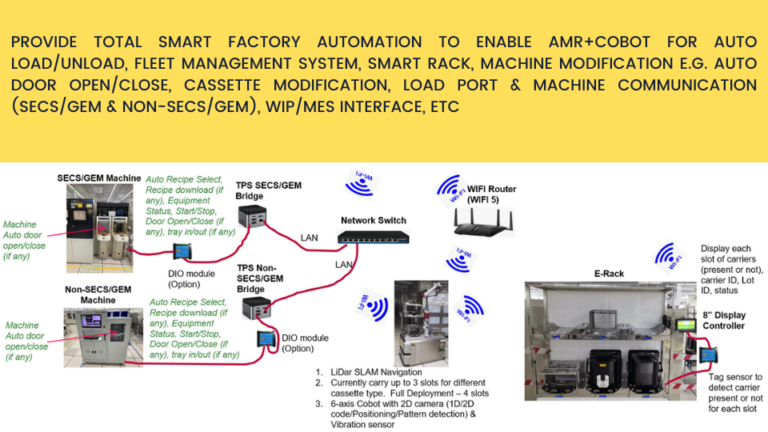

Provide Total Smart Factory Automation to enable AMR+Cobot for auto load/unload, fleet management system, smart rack, machine modification e.g. auto door open/close, cassette modification, load port & machine communication (SECS/GEM & Non-SECS/GEM), WIP/MES interface, etc

- Users defined application (software & hardware)

- Provide tailor made automation and equipment based on customer requirements

- Networking & connectivity solutions

- Provide software & system solutions as per customer requirements